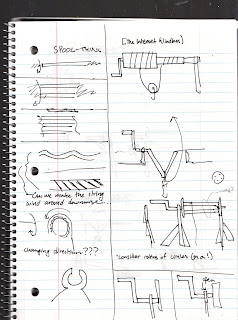

Tuesday night Anya and I decided to start designing our windlass. We began by sketching parts designs that we thought could work under the parameters. There was the spool, the stand and base, the handle/lever, and the connections.

Tuesday night Anya and I decided to start designing our windlass. We began by sketching parts designs that we thought could work under the parameters. There was the spool, the stand and base, the handle/lever, and the connections. Spool: It needed to be strong since it would be carrying most of the weight from the bottle. We didn't want all the string to wrap over its self too and create a weak point or to spread out too far. One design we came up with was an attempt to spiral the string across the spool but that would have require us carving into the delrin rod. We thought another way to achieve the spiraling string would be to cut a wavy a pattern out of delrin to guide the string across the spool. A second idea was to have two rods spaced apart so that each rotation of the handle would pull up more string. This would also distribute the weight across two rods. We played around with having three rods and having supports in the middle. In the end, we trusted the strength of a two pronged delrin spool which would also save us material. Our final spool design has a hole for the string and a notch to keep the string from going to the weak spot of the center of the spool.

We also played around with some other ideas for fun such as one that we found on the internet that has two rods, one that fits in the other and a pulley. All the sting is initially on the wide rod, through the pulley (which attached to the bottle) and then to the small rod. The crank turns the small rod transferring the rope to the that rod and would give us double the pulling power. We though about ways to minimize material. Since we were only rotating the string on the side instead of the center, the would right side of of the spool was useless. We tried cutting it short by making it sloped or trapezoidal. Also, since the goal was to get the bottle 10 cm above the table Anya had the idea of a V shaped spool that would lift the bottle all the way up in just one crank.

We also played around with some other ideas for fun such as one that we found on the internet that has two rods, one that fits in the other and a pulley. All the sting is initially on the wide rod, through the pulley (which attached to the bottle) and then to the small rod. The crank turns the small rod transferring the rope to the that rod and would give us double the pulling power. We though about ways to minimize material. Since we were only rotating the string on the side instead of the center, the would right side of of the spool was useless. We tried cutting it short by making it sloped or trapezoidal. Also, since the goal was to get the bottle 10 cm above the table Anya had the idea of a V shaped spool that would lift the bottle all the way up in just one crank.

Crank/Handle: To power the windlass and get the string up, we needed a crank. This was a pretty simple design. At first we toyed with the idea of gears to get more string up per wind, or ratcheting so that the crack wouldn't unwind on us but it wasn't essential to the challenge so we left it alone. If we did have gears, the handle was going to be on the outside of the circle to increase our advantage. To simplify things, the handle and the spool ended up being one piece with the handle centered.

Base/Stand: We decided to go for a pyramidal shape for the base. We initially had one piece that went parallel to the table but then as support we added a perpendicular piece. These two pieces fit together through notches. We played around with having the second peice slant more outwards, or having one leg. In the end we finalized it to have to equal length legs so that the base of the support stand would look like a square. The parallel piece has a hole in it to hold the spool.

Connections: We needed pieces to hold everything together. The connection between the two stand pieces would be a simple notch that they would fit into. The other connection we needed to worry about was the stand and the spool. The spool would be cut out of rectangular delrin and we needed it to move in a circle. We designed an open bushing that was a circle with a notch that would fit on the spool. This washer-thing would fit in the circular hole of the stand and rotate in there. We had assumed that it would be a tight and fit and be held in fine.

|

| Final Design |

|

| some modifications |

Great summary of your process with excellent sketches!

ReplyDelete