Our project was to create a device that could open a window curtain by responding to exterior and interior light. The curtain would be on a stand meant to replace a real window frame. It would be a rod with shower curtain rings and a curtain hanging off. The curtain would start closed, open when there is an exterior light (the lamp), then close when there is interior darkness (covering the sensor).

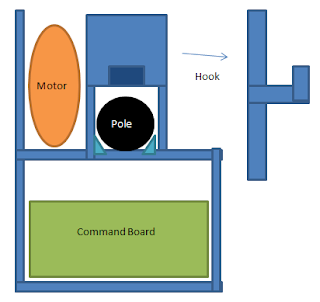

Our device is created to slide onto the rod and balance on it. There were four final compartments to the device. First was the box for the command board. Since this was the heaviest piece, the command board lay horizontally across the bottom. it had pegs that kept it from falling out of the bottom (attached by pegs and notches) and two piano-wired delrin pieces that could swing open and closed so that we could get the board in and out. Above this section were three vertical sections. In the image above, the left compartment was for the motor to sit in. All it had was two walls and a bottom. The motor wouldn't move around since it is attached to the machine through the axle that goes to the wheel. We used the nxt motor which was a little long but at an angle fit fine. The motor was connected to the command board through the side. The middle section is the wheel and rod compartment. The bottom 3cm of the compartment was left empty for the rod. There are four small right triangles in the corners of the walls and bottom to guide the rod so that it doesn't wobble. These side walls have holes centered in the remaining 5cm of the top. The wheels came from the lego set. They are 3cm wide with a 5cm diameter. There is a delrin piece that covers exactly where the the wheels go and have a hook attached to them. This hook holds on to the curtain loops that are right next to the vehicle. It helps it push the curtain and the prevents the rings from getting stuck in the wheels. The compartment to the right has two pieces of delrin connecting the walls. This is where we ended up putting our weight to balance the car. We used masses borrowed from the physics lab, totaling around 256 grams. There are two sensor attached to the command board- one that reads light and one that reads dark. These sensors were not attached to our machine but to the stand.

Critical Elements

We had a few main points to research here

1) What type of window covering device?

We decided on a curtain and rod after looking at other sorts of devices on home depot and lowes. A curtain is found in most homes and in simple for humans to open and it was something we could easily recreate with out resources.

2)Vehicle

We tested placement of the wheels- above, below, or one on each side of the rod- used this to guide our basic structure. We created a box-like design out of legos and revise this to get our current shape. We wanted a shape that was simple and would balance. Balance it turned out was our biggest challenge.

3)Sensors

We started off with the light sensors that were in the lego cabinet. The we found the small lego sensors which were much better and used them to get a light reading. Though this would ideally be reading sunlight and darkness in your room, for the exhibition we worked with the value of the lamp given.

Works-like model

For our works-like model we built a lego model. This kept falling apart so we knew that we wanted delrin to be our final material. Later we thought about using wood since we though it would be easier to attach but in the end delrin was out material. Our lego model has the same compartments as above except for the weight area. Also the hooks are not shown but they were part of out original design- they were just difficult to build out of lego. With the code we created on pico blocks, we were able to get the device to drive across the rod and return. Our kinks were that it was tilted and not balanced, and that it would go inconsistent distances.

initial pico code using time instead of count

We designed our model and pieces on Solid Works. We knew that this device was going to be a bit bulk so we tried to minimize our dimensions as much as we could. Also we could the peg and notch method for joining our pieces which is more aesthetically pleasing compared to heat staking which can get messy or to piano wire. Our initial looks-like model looks just like our final model as described above except for the addition of the longer side wall for the weight.

final delrin device

The other piece we had to build was out stand for the curtain device. This looked like two upside -down T 's connected by a Z. We displayed our final project out side Amy's office to get the full 'window' look.

Video

Photos

Final device with all its parts

over head shot

Final Code with count

in its natural habitat

The final product

Impressions and Improvements

I was surprised but how the project went. I was afraid that it was going to be stressful and difficult but it wasn't. Taking it step by step and seeing each step as improving upon our design rather than a failure made the process enjoyable. I learned a lot of new tricks such as how to properly measure for pegs and notches on solidworks and how to set a state on pico blocks (open?=1 or =0 and to have that be a condition). It was fun to test different iterations of the design and try to come up with ways to fix it. I am happy with our design and that it worked and how it worked but there are a few thing that I would have liked to work on.

I really enjoyed the exhibition and talking to people we new ideas about our project. Many people said that they really liked the idea and wished that they had one for their house. If I had more time and resources, I would have liked to get a command board that is much smaller. The board was the biggest piece and it threw off the balance. It also made the car big and minimizing the size would look better. I think with a smaller command board we could work with the balance around just the motor and the rod. I also had an idea that it would be cool to make a spherical vehicle- that way it is always right side up and never looks tilted. It would also make this aesthetically pleasing not make it an ugly appliance in your house. Another idea we had from talking to people was customization settings. We did think about this in out initial design but be had no idea how to make the settings changeable without pico blocks. Also an override button would be cool. Other people wanted their windows to be closed right as the sun went down rather that when they turn out the lights to prevent light pollution, some like the window closed at noon with the high sun and then open again in the evening. One person mentioned setting a time delay over the summer for the the sunrises at 5 in the morning and you want to sleep in, others liked the idea of a natural alarm clock. One person asked if they could get the pieces commercially so he could make his own. It was exciting to see people talking about our device in a real-world context.

.jpg)