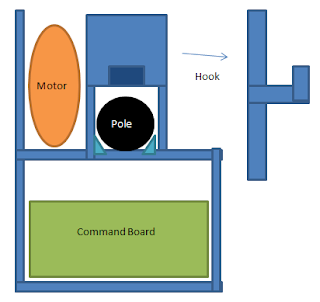

Above is our initial design. I drew this out because it was simple to create and put together, and we hoped to balance it out with weights later. Balancing with weights wasn't a good design idea so we manipulated the cardboard and lego models to find a structure with a good balance. We ended up moving one of our sides in more to save space and so that it would be off-centered and balance on its own. We tested this out with the lego model and it worked.

We decided not to bend delrin since that would be difficult to connect and have all the pieces fit. There is a back behind the command board to hold it in. We also want to use a dovetail joint to attach the back piece and pegs and notches on the other pieces. The horizontal pieces will have notches and the vertical pieces will have pegs at their ends.

There is also the hook piece. This will cove the wheel- for aesthetics- and to hold the curtain rings. It will be a few mm above the pole as to not interfere with it.

The pieces will be printed tomorrow. Hopefully they will fit and we will begin to move on to details- revising the code, building the stand, and fixing the balance.

No comments:

Post a Comment